Product Details

Place of Origin: China

Brand Name: SFT

Model Number: DC7221(5C)-N

Payment & Shipping Terms

Minimum Order Quantity: negotiable

Price: negotiable

Packaging Details: carton,pallet

Delivery Time: 20-45DAYS

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 50000PCS/MONTH

Bore Size: |

72.217 Mm |

Precision Rating: |

P0 |

Number Of Row: |

Single Row |

Material: |

GCr15 |

Inner Diameter: |

72.217 Mm |

Inner Race Max. Overrunning (rpm): |

2400 |

Thickness (mm): |

25 |

Weight (Kg): |

0.14 |

Bore Size: |

72.217 Mm |

Precision Rating: |

P0 |

Number Of Row: |

Single Row |

Material: |

GCr15 |

Inner Diameter: |

72.217 Mm |

Inner Race Max. Overrunning (rpm): |

2400 |

Thickness (mm): |

25 |

Weight (Kg): |

0.14 |

Detailed Info.

| Item | DC7221(5C)-N |

| Material | GCr15 |

| Bore dia. | 72.217 mm |

| Outer dia. | 88.877 mm |

| Width | 13.5 mm |

| Torque capacity | 675 N.m |

| Overrunning speeds (imax) | 2600 r/min |

| Overrunning speeds (amax) | 1300 r/min |

| Weight | 0.14 kg |

| Package | Carton box or as your requirements |

Brief Introduction

Alternatively, races can be made in case hardened steel shafts, or housings, to the specification below. Surface hardness of the finished part should be HRC 60 to 62, for a depth of 0,6 mm minimum.

Core hardness to be HRC35 to 45. Surface roughness not to exceed 22CLA. Maximum taper between races: 0,007 mm for 25 mm width.

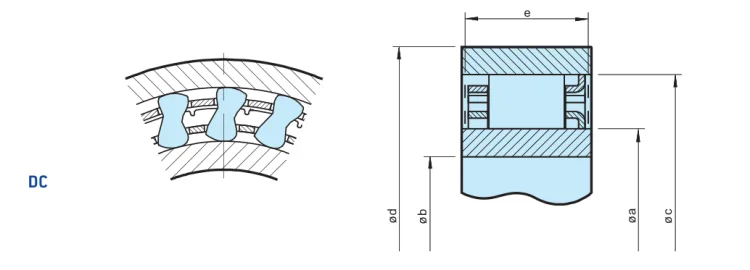

Dimensions and Capacities

|

Size

|

TKN1) |

Overrunning speeds |

Sprag space

|

NO. of clips

|

No. of sprags |

Weight | ||||||

| nimax2) | namax3) | Øa+0.008 -0.005 |

Øc± 0.013 | emin | Ødmin | Øbmax | ||||||

| [Nm] | [min-1] | [min -1] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg] | |||

| DC2222G-N | 63 | 8600 | 4300 | 22.225 | 38.885 | 8.33±0.075 | 10 | 50 | 15 | – | 12 | 0.03 |

| DC2776-N | 119 | 6900 | 3400 | 27.762 | 44.422 | 8.33±0.075 | 13.5 | 58 | 18 | – | 14 | 0.055 |

| DC3034-N | 124 | 6300 | 3100 | 30.34 | 47 | 8.33±0.075 | 13.5 | 62 | 20 | – | 14 | 0.06 |

| DC3175(3C)-N | 159 | 6000 | 3000 | 31.75 | 48.41 | 8.33±0.075 | 13.5 | 63 | 21 | 3 | 16 | 0.06 |

| DC3809A-N | 275 | 5000 | 2500 | 38.092 | 54.752 | 8.33±0.075 | 16 | 71 | 25 | – | 18 | 0.085 |

| DC4127(3C)-N | 224 | 4600 | 2300 | 41.275 | 57.935 | 8.33±0.075 | 13.5 | 75 | 27 | 3 | 18 | 0.09 |

| DC4445A-N | 363 | 4300 | 2100 | 44.45 | 61.11 | 8.33±0.1 | 16 | 79 | 29 | – | 20 | 0.095 |

| DC4972(4C)-N | 306 | 3800 | 1900 | 49.721 | 66.381 | 8.33±0.1 | 13.5 | 86 | 33 | 4 | 22 | 0.1 |

| DC5476A-N | 525 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 16 | 92 | 36 | – | 24 | 0.11 |

| DC5476A(4C)-N | 525 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 16 | 92 | 36 | 4 | 24 | 0.13 |

| DC5476B(4C)-N | 769 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 21 | 92 | 36 | 4 | 24 | 0.18 |

| DC5476C(4C)-N | 990 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 25.4 | 92 | 36 | 4 | 24 | 0.2 |

| DC5776A-N | 604 | 3300 | 1600 | 57.76 | 74.42 | 8.33±0.1 | 16 | 98 | 38 | – | 26 | 0.11 |

| DC6334B-N | 806 | 3000 | 1500 | 63.34 | 80 | 8.33±0.1 | 21 | 104 | 42 | – | 26 | 0.175 |

| DC7221(5C)-N | 675 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 13.5 | 115 | 48 | 5 | 30 | 0.14 |

| DC7221B-N | 1279 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 21 | 115 | 48 | – | 30 | 0.185 |

| DC7221B(5C)-N | 1279 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 21 | 115 | 48 | 5 | 30 | 0.21 |

| DC7969C(5C)-N | 2038 | 2400 | 1200 | 79.698 | 96.358 | 8.33±0.1 | 25.4 | 124 | 53 | 5 | 34 | 0.28 |

| DC8334C-N | 2055 | 2300 | 1100 | 83.34 | 100.000 | 8.33±0.1 | 25.4 | 132 | 55 | – | 34 | 0.27 |

| DC8729A-N | 1250 | 2200 | 1100 | 87.29 | 103.96 | 8.33±0.1 | 16 | 134 | 58 | – | 34 | 0.165 |

| DC10323A(5C)*-N | 1612 | 1800 | 900 | 103.231** | 119.891 | 8.33±0.1 | 16 | 155 | 68 | 5 | 40 | 0.205 |

| DC12334C*-N | 4800 | 1500 | 750 | 123.340** | 140.000 | 8.33±0.1 | 25.4 | 184 | 80 | – | 50 | 0.4 |

| DC12388C(11C) | 4875 | 1500 | 750 | 123.881 | 142.88 | 9.50±0.1 | 25.4 | 186 | 80 | 11 | 44 |

0.4 |

Mounting Example

![]()

![]()

![]()